PC3 Coatings

Applications:

1

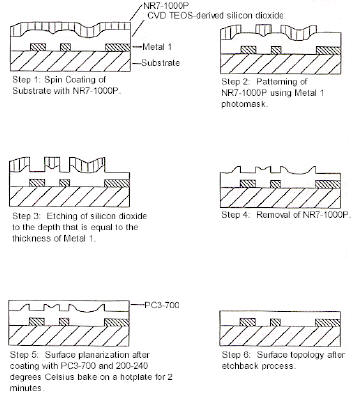

Planarizing Layer - etchback process to transfer planarity from

planarizing layer into

underlying dielectric. 2

Protective Coating - dicing and sawing operations to prevent

mechanical damage to the fabricated

device. 3

Adhesive Layer – attaching the device side of the wafer to a wafer

holder in back

grinding operations.

Properties: Superb planarizing capability.

Thickness range: 0.5-20 µm

Impact on productivity:

For Planarization Applications: Elimination of Chemical Mechanical Polishing

(CMP) in some applications.2 Suppression of

microloading effects in etchback process.

For Protective Coating Applications: Elimination of film peeling and

cracking during dicing operations.

For Adhesive Applications: 1

Easy removal in Resist Developer RD3 or RD6 after back

grinding and wafer separation. 2

Elimination of waxes from backside processing.

PC3 Coatings

Coating

Thickness

PC3-700 0.6µm - 1.6µm

PC3-1500

1.1µm - 3.2µm

PC3-6000 5.0µm - 12.2µm

|

Planarizing Coatings for

Sacrificial Etchback Applications |

|

Thickness Range |

0.7 - 12

µm |

|

Performance |

Superior planarizing

capability.

Outstanding etchback compatibility with underlying dielectric. |

|

Applications |

Surface planarization for planarization etchback process.

Protective coating.

Binding layer on the active side of devices for backgrinding.

Protective coating in wafer dicing. |

Development of novel UV

cross-linkable materials

for enhancing planarity

in via applications via

the correlation of

simulated and

experimental analyses

Beam Lead Quartz Chips

for Superconducting

Millimeter-Wave Circuits

If you don't find what you're looking for,

Contact Us.

We may have a suitable product that's not listed, or we may be

able to develop a material to fit your specific needs.

Tel : (02)2217-3442 / Fax : (02)2704-4070

|