|

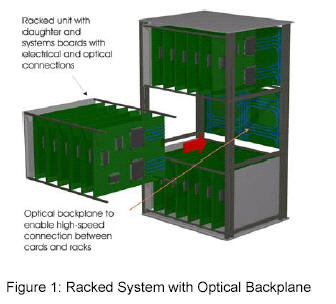

As end users continue to

demand greater bandwidth in optical and wireless communication,

so data-rate demand increases in high-end systems for switching

and routing. A major bottleneck that is fast approaching in such

systems is the backplane which links daughter boards with

switching and control boards. To ease this bottleneck the next

generation of backplanes is being developed which includes

optical waveguides – a technology which enables ultra-high

bandwidth and the design freedom of more distributed

architectures.

Optical backplanes

developed in the past, often for military applications, are seen

to be a poor solution for telecom/datacom systems due to their

poor compatibility with low-cost PCB manufacturing techniques. A

market review by BPA Consulting predicts that there will be an

explosion of use in optical backplanes by a factor of ~100 times

from 2000 to 2005 as applications extend from aerospace into

telecom and datacom.

Leading telecom system

suppliers are setting the agenda with performance specifications

that can only be met using optical techniques. Some high-end

systems already use optical connections such as direct fibre

links and optical fibre mesh technology. However, these first

generation optical technologies deliver only point to point

links, require expensive connectors and are unwieldy.

This is driving major

PCB manufacturers and associated companies to invest in new

solutions in optical technology to create low cost optical

backplanes to meet their customers needs.

Top of the shopping list

of the PCB companies is a material and robust manufacturing

process for the fabrication of the waveguides themselves. While

silica is held up by some to be a solution, principally due to

its low loss, many see polymers as being the prime candidate.

The requirements on the polymer are however demanding. In

essence, the polymer must be low loss, compatible with existing

PCB processes and photowritable. Terahertz Photonics have

developed a particular polymer, Truemode BackplaneTM, which

uniquely meets these requirements.

If you don't find what you're looking for,

Contact Us.

We may have a suitable product that's not listed, or we may be

able to develop a material to fit your specific needs.

Tel : (02)2217-3442 / Fax : (02)2704-4070

|