|

Advanced Polymer Integrated Optics

(APIO)DLC's

Advanced Polymer Integrated Optics is a platform technology

for the design & fabrication of polymer optical chips & hybrid

optical chips containing polymer.

It is the combination

of a reliable and scalable chip fabrication process with a

large toolbox of optical designs. It has the ability to

integrate a range of optical functionality, with a flexible

layout and a small footprint. It can deliver high volume

manufacturing, with standard semiconductor fabrication

equipment, at high yields and low cost.

Products

Passive PLC chips

Splitters

Mux/demux (1550nm / 1310nm)

Custom Device Design

Innovative and professional design

services

Low cost, small footprint, high performance planar

solutions

Customised layout and footprint

Foundry

Services

Mask design and layout

Fabrication

Dicing

Fibre attachment

Full chip characterisation

Wafer

characterisation

Advantages

Small footprints

possible due to high index contrasts

Small bend radius

Low device losses

Suitable platform for complex

functionality (better than Silica on Silicon)

Dynamic

attenuation using thermo-optic coefficient

Modulation by

incorporation of electro-optic chromophores

Scaleable

to Volume Manufacture

Few steps

High yields

Direct UV

Patterning (resist free process with no ion etching)

Low

capex cost

Small facility requirements

Low labour cost

Wafer size independent

Solvent free processing

High

quality films

Environmentally safe

Low cost shipping and

handling

Nominal Specifications

|

Fully Tuneable Refractive Index Range (25°C) |

Cured Film, 1550 nm: 1.474 - 1.528

Cured Film, 633 nm:

1.491 - 1.543

IPG™ Resin, 633 nm: 1.485 - 1.535 |

|

Thermo-optic coefficient (dn/dT) |

~ -3 x 10-4 /°C (over whole index range) |

|

Birefringence |

~ 1 x 10-4 |

|

Resin Absorption Loss |

1550 nm: ~ 0.5 dB/cm

1310 nm: ~ 0.25 dB/cm

850 nm: <

0.1 dB/cm

633 nm: < 0.1 dB/cm |

|

Resin viscosity |

1,000 - 10,000 cP (controllable) |

|

Film thickness |

0.5 - 50 um (single spun layer) |

|

Thermal stability |

>300 °C |

Patterning of Waveguides

|

|

|

|

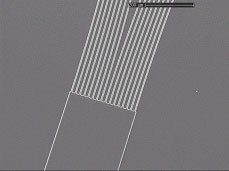

1x16 MMI splitter output |

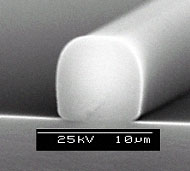

Waveguide core (proximity exposure) |

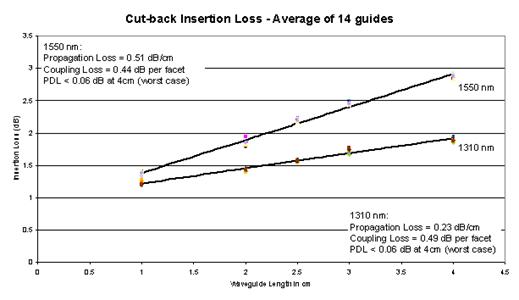

Insertion Loss

Fabrication

Process

If you need any special

spec, we can customize

If you don't find what you're looking for,

Contact Us.

We may have a suitable product that's not listed, or we may be

able to develop a material to fit your specific needs.

Tel : (02)2217-3442 / Fax : (02)2704-4070

|

|