|

ICP Etched Waveguides |

Arrayed Waveguides (Microscope) |

Standard Optical Waveguides Resins

ZP-49 & ZP-51 series are thermally curable polymers based on highly fluorinated polyethers. Newly

formulated ZP-49 & 51 are improved the film quality, controllability of refractive index and solution

shelf life in comparison with former ZP1010M series. They are useful for optical waveguides and

optical thin film applications due to the low optical loss, high thermal and environmental stability.

To be used for various waveguide structures, precise and continuous control of refractive index is

available by blending of polymer solutions with standard refractive index.

Availability and Storage

ZP-49 and ZP-51 solutions are available in 100 and 250 g quantities. These solutions should be

stored in a dark and cool place under 25°C in the bottle with a tight cap . Moisture should be

avoided because it may affect the product performance.

Features

Low-optical loss

Thermal & Environmental stability

Controllable refractive index

Excellent mechanical properties

Applications

Optical power splitters

Variable optical attenuators

Optical Switches

Optical interconnections

Multi-mode waveguide devices

Performance Specifications

|

|

Standard Item |

ZP-49 |

ZP-51 |

|

Liquid |

Viscosity (cps @

25°C) |

240 ~ 300 |

260 ~ 320 |

|

Filtration |

0.1 ~ 0.2

µm

absolute PTFE filter |

|

Curing Temp.(Tc) |

250

°C for 2 hr |

|

|

|

|

|

Film |

Propagation Loss

(measured from slab waveguide) |

0.3 dB/cm

@1.55

µm

wavelength |

|

0.15 dB/cm

@1.3

µm

wavelength |

|

Refractive Index

@ 1.55

µm |

1.490 |

1.510 |

|

Birefringence (nTE-nTM) |

0.004 ± 0.001 |

|

Refractive index

uniformity |

<

0.00002 |

|

Thermo-optic

coefficient |

-0.7 ~ -1.2 x 10-4/

°C |

|

CTE (ppm/°C, by TMA) |

93 |

78 |

|

Glass Transition

Temp. (Tg) |

146°C |

206°C |

|

Degradation Temp.

(1 %) |

392°C |

444°C |

|

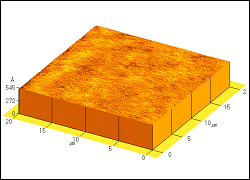

Surface roughness

(AFM) |

<

0.3 nm at 8

µm thickness |

|

Film thickness |

<

10 ㎛ per coating (multi-coating available) |

|

Reliability |

See the back page |

Reliability of Optical Waveguide Resins (ZP-49 and ZP-51)

During the test, all of the films were not peeled off from the Si wafer substrate and their refractive

index were not changed.

The

test films were made by spin coating and curing on the Si wafer after treatment of the adhesion promoter.

If you need any special spec, we can customize

If you don't find what you're looking for,

Contact Us.

We may have a suitable product that's not listed, or we may be

able to develop a material to fit your specific needs.

Tel : (02)2217-3442 / Fax : (02)2704-4070

|