|

RANGE OF IN LINE COATING

CONTROLERS

The ASM controlers are specifically designed for keeping

constant the density (ASM 2000 series), the viscosity (ASM

2500 series) or the combination of both density and viscosity

(ASM 3000 series) of anti-scratch and/or anti-fog coatings

used for the treatment of transparent substrates

All ASM systems control the level of the coating tank via

specific sensors.

As soon as the level in the tank falls under the reference

(either bacause of solvant evaporation or because of the

coating process itself, the system will refill the tank with

either base coating or solvant, depending on the actual value

of the controled parameter (density or viscosity) compared to

the set-point.

|

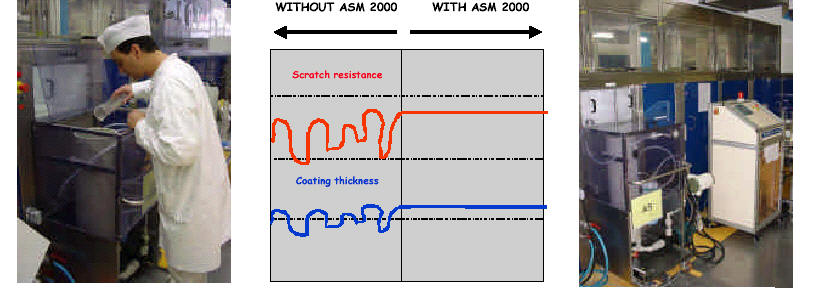

Example of 2 x ASM 2000 systems on a dip-coating line |

|

|

In most case, the ASM in-line controler comprizes:

one chassis on wheels that houses the control electronics, the

refill canisters (one for solvant,one for coating), the refill

pumps and valves and supports the color touch-screen

operator’s interface.

One in line sensor for density or viscosity per tank to be

controled

One set of non-contact level sensors per tank to be controled |

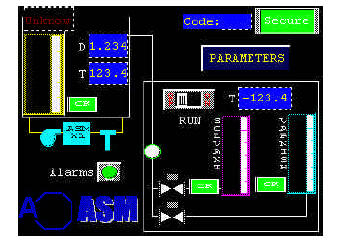

The color touch screen with multiple windows type of user

friendly

interface allows a simple but efficient control over the

process (View of main screen of the ASM 2000-1 system) |

|

WHY

SHOULD YOU USE ASM CONTROLERS ?

|

|

|

Before: manual control |

After: automatic control |

By eliminating all operator’s interactions with the coating

process, with their inherent risks for mistakes

and by adding only by very small volume of either solvant or

coating (10 to 50 mL), the ASM controler drastically reduces

the fluctuation of the performances of the coating process.

Other inherent benefits are:

Eliminates the costly man-power required with manual

control(all refills and controls are automatic,day and night,

week end included)

Eliminates production down-time (the small quantity added to

the tank does not impact the coating process so that operation

can be continuous)

Eliminates all risk for coating mishandling situations such

as:

# chemical shock if a too large quantity of solvant is added

to the tank in one shot

# refill with the wrong chemical

# risk for the formation of air bubble s if the level becomes

to low Increase the consistency of the process Increase the

life time of the coating solution Allows to save on non

quality issues and rework |

|

ASM

X1 in line Density sensor |

ASM X2 in line viscosity senso |

|

SPECIFICATIONS

Here after are the specifications of our range of standard systems

for optical coating applications.

Other systems are available upon request. ASM is also ready to

study a specific controler for your process requirement or coating

equipment.

|

|

In Line Controlers

Density Controlers

Viscosity Controlers

Combined Density Viscosity

Controlers

Photoresist Development Controlers |