|

Application Fields

STRUKSILON 8026 is used as a

silicone surfactant for the production of polyurethane

shoe sole systems as well as other microcellular foams. It

is especially recommended for shoe sole formulations based

on polyester and blends of polyether/polyester polyols. STRUKSILON 8026 was specifically developed to offer

excellent performance in high as well as low density

systems.

Additionally, TRUKSILON 8026 can

be successfully applied in pour-in-place systems, PUR

spray formulations and in a variety of continuous

laminated boardstock formulations.

Chemical and Physical Properties

According to its chemical structure STRUKSILON 8026 is a polyether modified polydimethyl

siloxane resistant to hydrolysis.

STRUKSILON 8026 is a clear, colourless to slightly

yellow liquid of middle viscosity, has strong surfactant

properties and is miscible with water at room temperature.

General Chemical

Structure

Typical Properties

Viscosity at

25°C mm2/s 350

Density at 25°C kg/m3 1,071

Flash Point (DIN/ISO 2562)

°C > 100

Refractive Index

at 25°C 1,454

Technical Properties

STRUKSILON 8026 was specifically designed to be used in shoe sole and

other microcellular systems. It is mainly recommended for

polyester and polyester/polyether blend based

formulations.

STRUKSILON 8026 offers an excellent regular and fine cell structure and

a good skin formation. Even in low density foams skin

defects and voids on or slightly under the surface can be

avoided. Very low shrinkage will be observed even at short

demould times using low density formulations.

Due to this

outstanding performance

STRUKSILON 8026 is recommended as a wide density range silicone

surfactant for all polyester polyol based shoe sole

applications in formulations from 0,34 g/cm³ to 0,58

g/cm³.

Performance

Test Results:

Test objective:

The test was

carried out as a comparison test of

Struksilon 8026 and two reference materials. The comparison material A is

a silicone surfactant mainly recommended for high density

shoe sole systems. Comparison B is a surfactant mainly

recommended for low density shoe soles.

The major task

was to compare the influence of the surfactant on the cell

structure, the skin formation and the general processing

of the systems.

Higher density:

The test for

higher density was carried out in a standard polyester

polyol based system. Demould densities of 0,56 g/cm³ were

obtained.

General

results: All three surfactants showed an excellent skin

formation, a fine cell structure and excellent processing.

Lower density:

For the

production of the lower density foams a standard shoe sole

system with a demould density of 0,36 g/cm³ was chosen.

Test

formulation:

polyester polyol linear, adipic acid

based, OH-value = 56 mg KOH/g 83,23

monoethyleneglycol 13,9

triethylenediamine

33,3% triethylenediamine in MEG 2,05

water H2O 0,55

silicone silicone surfactant 0,27

100,00 parts

prepolymer 20% NCO 132 parts

free rise density:

0,21 g/cm³

demould density: 0,38 g/cm³

Processing:

prepolymer

temperature: 60°C

polyol temperature:

55°C

mould temperature: 50°C

demould time: 3,5 min

The tests were carried out using a

standard low pressure mixing device.

With all three

materials a demould time of 3,5 min was reached.

Skin formation:

The comparative silicone surfactant A

mainly recommended for higher densities showed voids and

skin defects in the majority of the produced samples.

For STRUKSILON 8026 no skin defects were observed.

Dimensional stability:

None of the

samples showed a shrinkage of more than 2%.

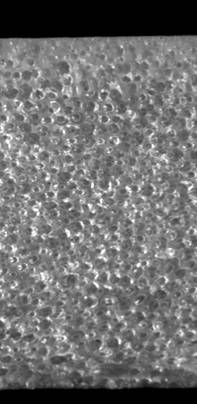

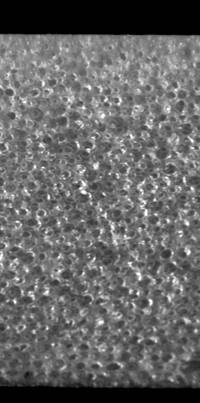

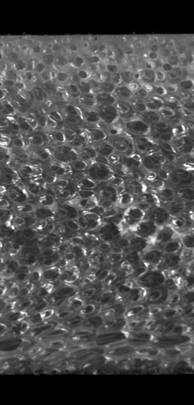

Cell

structure:

DLC STRUKSILON 8026

Comparison B Comparison

A

STRUKSILON 8026 exhibits an

excellent fine cell structure. Comparison B offers an almost

identical cell structure, while comparison A shows coarse and

irregular cells

Results

STRUKSILON 8026 is an

excellent wide density range silicone surfactant for shoe sole

systems. The product allows to make shoe soles characterised

by excellent cell structure, very good physical properties as

well as improved processing in both, high and low density shoe

sole systems.

Recommended Dosage

Usually, STRUKSILON 8026 is applied

in quantities of 0.1 to 1.0 php (parts on 100 parts polyol).

We recommend to adjust the optimum dosage to the

corresponding formula. However, a concentration of 2 php

should not be exceeded.

Product Safety and Handling

STRUKSILON 8026 is not a hazardous

material for the purposes of hazardous materials

regulation.

Further information regarding safety,

toxicology, special properties of the product, transport

and storage are given in the safety data sheet.

Packaging, Storage and Transport

Storage stability 12 months in

closed original containers if transported and stored at

temperatures between 1 and 30°C.

Packaging

200 kg drums

1000 kg containers (IBC)

This information is based on our present knowledge and

experience. The values given are not intended to prepare

specifications. Our technical advice and recommendations

whether verbal, in writing or by way of trials do not

absolve the customer, on account of the many outside

influences which may affect the product use and

application, from their own testing and trials. A legally

binding assurance based on information contained herein

regarding particular properties or the suitability for

definite customer applications cannot be assumed. The

customer bears the responsibility for the observation of

possible patent and trademark rights in addition to

relevant laws and regulations relating to the products.

If you don't find what you're looking for,

Contact Us.

We may have a suitable product that's not listed, or we may be

able to develop a material to fit your specific needs.

Tel : (02)2217-3442 / Fax : (02)2704-4070

|