Non-toxic, inert polymer systems designed to remove dust,

fingerprints, residues and other contamination from surfaces.

First Contact™ cleans diffraction gratings, nanostructures as well

as all precision optics like first surface mirrors and special

coatings. First Contact™ also protects optics from physical and

chemical damage in shipping and storage.

First Contact? covers from 5 to 6 square

inches (32 - 39 square cm) per 1 ml

of solution when used on smooth surfaces like mirrors. This

application rate

creates a thick, strong film which will lift easily from the

surface with no

tears or breaks. Heavier application may be necessary for larger

surfaces.

Surfaces like gratings or screw threads need much heavier

application to

create a film which is strong enough to peel off the surface

without

tearing. We recommend the user make several applications at time

intervals,

allowing the previous application an opportunity to set up. More

drying time

is needed when creating thick films.

Does First Contact?

leave a residue after cleaning?

No, First Contact? leaves no optically

active residue. First Contact?

actually leaves most optics cleaner than new from the factory,

including

pin-hole optics.

How

does First Contact? interact with light?

Colorless First Contact? is optically

transparent, it does not interact with

electromagnetic waves from 220 nm to 2500 nm. There is no

scattering in this

region. (Colored First Contact? solutions and films cannot make

this claim.)

What protection

does First Contact™ provide during handling, storage and shipping?

When properly applied, First Contact™

protects against scratching, abrasion, dirt, and water damage.

First Contact™ also protects against corrosion caused by water

vapor, oxygen, and sulfur.

First Contact™ dries to a strong solid film which

adheres to the surface tightly. The film covers the surface

intimately, providing an effective barrier to particulates.

Unlike other protective films in use today, the

tough, resilient First Contact™ film prevents scratches due to

particulate matter or abrasion from surfaces rubbing against the

protected surface. First Contact™ IS the protection, it does need

to be protected with expensive packaging designed to suspend the

optic to prevent any contact during transit.

Can

I lower packaging and shipping costs by using First Contact™?

Photonic Cleaning Technologies believes you

can! First Contact polymer film is tough, resilient, and protects

against many physical and chemical attacks. It provides a positive

physical barrier between the optic and the world. This physical

barrier allows the use of less sophisticated, less expensive

packaging options. By shipping with First Contact™ protection on

your optics, package cost and time spent packaging should drop

significantly.

Does First Contact™ protect against water

and water vapor penetration?

Yes, First Contact™ provides an effective

barrier to water and water vapor.

Does First Contact™ protect against oxygen?

Yes, First Contact™ provides effective

protection from oxygen. The dry, First Contact™ film is impervious

to oxygen.

Does First Contact™ Protect against sulfur

penetration?

Yes, First Contact™ is impervious to sulfur

vapors and provides effective protection against sulfur.

If First Contact™ sticks after storage, how

can I remove it safely?

First Contact™ polymer is inert so

it is unlikely it will stick too tightly to the surface even after

a lengthy storage period. However, if necessary, the polymer can

be re-dissolved using fresh First Contact™ solution. When the

fresh application dries, the polymer film will peel off quickly

and easily.

Can First Contact™ clean glass and coated

optics?

Yes, First Contact™ was developed with this purpose

in mind. The developers were researchers trained to use precision

optics in their research and knew there had to be a better way to

clean than drag wipe methods. They worked for several years to

attain a breakthrough technology for cleaning precision optics and

have spent several additional years proving the technology works

as well as improving the product.

First Contact™ is a single component cleaning

solution. Just apply First Contact™ from the bottle; there is no

need to ever touch the optic surface directly with a brush, mesh,

or tissue. First Contact™ penetrates every surface feature down to

50 nm and smaller. When the dried film is removed, the surface is

optically clean and the optic coatings remain intact.

First Contact™ is effective on rough surfaces like

diffraction gratings and frosted glass, too!

Can First Contact™ clean telescope optics?

Yes, First Contact™ cleans all telescope

optics, from mirrors to diffraction gratings to camera lenses,

quickly and effectively.

First Contact™ restores primary surface mirrors to

virtually new condition and can be applied to the surface while

the mirror is mounted in the telescope. Regular use of First

Contact™ can extend mirror life and reduce or eliminate the need

to recoat the primary surface.

Can First Contact™ clean metals?

Yes, First Contact™ cleans all metals.

Will First Contact™ remove blocking wax from

optics?

Yes, First Contact™ removes blocking wax

like that on the pictured x-ray optics much faster, more

effectively, and more completely than other methods.

All blocking wax is gone and so are all particles &

residues when First Contact™ is removed.

You may want to take advantage of First Contact’s™

impermeability to water, water vapor, oxygen, and sulfur to coat

the cleaned optic during storage. The dried First Contact™ film is

quickly and easily removed, within seconds, when the optic is

needed.

Will First Contact™ remove residue from

other attempts to clean optics?

Yes, First Contact™ is proven to remove

residues remaining when other products were used to ‘clean’ or

protect the optic.

Only First Contact™ protects, cleans, and leaves no residue!

Can First Contact™ clean crystals and

minerals?

Yes,

First Contact™ cleans crystals and minerals as long as the

material is not soluble in polar organic solvents. First Contact™

has been used to successfully clean laser rods and precious gems.

Can First Contact™

clean plastics?

Cleaning plastics is an area for caution.

First Contact™ can clean some plastics such as nylon and Delrin®

which are not soluble in polar organic solvents. However

polycarbonates and polyethylenes will dissolve in the First

Contact™ solvents.

If First Contact™ is going to be used on or near

plastics, use extreme caution. If possible, test a sample of the

plastic before using First Contact™ on the optic or optic

assembly. Photonic Cleaning Technologies will not accept

responsibility for damage to an optic or instrument due to

dissolved plastic components.

Can

First Contact™ clean camera lenses?

Camera lenses, lens

housings, and mounts may be composed of or contain plastics.

Caution must be exercised when using First Contact™ to clean

camera lenses.

Professional and research equipment lenses are

typically made with glass and high quality coatings. First

Contact™ is safe to use with these lenses. Many professional grade

lenses have metal housings and mounts which will not dissolve in

the First Contact™ solvents; it is best not to coat all the way to

these edges as the First Contact™ film will be more difficult to

remove. Even so, exercise caution and do not coat all the way to

the lens housing or lens mount if there is any chance these

structures are made of or contain plastics. Photonic Cleaning

Technologies will not accept responsibility for damage to an optic

or instrument due to dissolved plastic components.

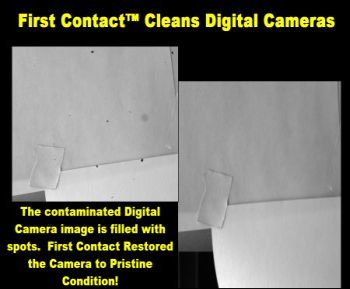

First Contact™ cleans digital cameras, including IR

filters and C-mounts!

Can

First Contact™ clean camera CCD?

Yes First Contact™

does clean detector windows and unprotected CCD boards effectively

and completely. We have done it many times. However, the user must

proceed with caution and knowledge about the CCD he/she is going

to clean.

CCD boards which are not covered by a detector

window are very delicate and the user must understand issues

regarding static charges and CCD’s if attempting to clean this

type of CCD. If you are not familiar enough with CCD, it is

possible to create static charges when removing the dried film,

which can damage the CCD. If you did not know this before reading

it here, we do not recommend cleaning the CCD by yourself until

you get some more instruction.

Some CCD mounts are made of plastic. As always when

using First Contact™, the user must be careful not to brush the

First Contact™ solution onto the plastic mount. First Contact™

solution may adhere to some plastics too tightly to peel off or

could even dissolve the material. This is usually not a

consideration for high quality laboratory equipment.

Jet

Propulsion Lab

,

Lawrence Livermore National Lab, (LLNL)

,

LLNL National Ignition Facility

,

Los Alamos National Lab

,

NASA Lewis Research Center

,

Sandia National Lab

Boeing Aircraft

,

Boeing Space and Missile Systems

,

Daimler Benz Aerospace

,

Lockheed Martin Missiles and Space

,

Coherent Laser

,

Continuum Laser

,

Corning

,

Crystal Systems

Epner Technology

,

KLA Tencor

,

New Focus

,

Phillips

,

Raytheon

,

Spectra Physics Laser

California Institute of Technology

,

Harvard University

,

The John’s Hopkins University

Massachusetts Institute of Technology

,

MIT Lincoln Labs

,

Stanford University

,

SUNY Buffalo

,

University of Arizona

,

University of Georgia

,

University of Maryland, College Park

University of Rochester

,

University of Texas

,

University of Wisconsin-Madison

If you don't find what you're looking for,

Contact Us.

We may have a suitable product that's not listed, or we may be

able to develop a material to fit your specific needs.

Tel : (02)2217-3442 / Fax : (02)2704-4070

|