|

光学或电子束曝光形成光刻胶的图形,金属薄膜沉积之后将光刻胶用除胶剂等溶解清除。

剥离用负胶跟光刻原理有关。正胶是曝光部分被显影掉。光刻胶层顶部比底部的曝光量更充足,显影后形成上面小下面大的“正梯形”截面。镀金属后难剥离。负胶则相反。

對於特定種類的金屬要使用蝕刻方式完成電路圖案會相當困難,像是III-V與II-VI族化合物半導體或是MEMS微機電的製備,如使用的金屬為鉻Chromium不像鋁容易蝕刻,因此需要採掀離Lift-Off製程。

Lift-Off的製成良率,取決於金屬薄膜是否垂直且均勻perpendicularly

&uniformly蒸鍍於有覆蓋光阻及沒有光阻的表面:從鍍膜垂直的要求,若金屬薄膜蒸鍍在光阻的側面side

wal,則無法在後續步驟使用丙酮或有機溶劑移除光阻,從而形成元件製作上的缺陷。從鍍膜均勻的要求,若鍍於晶圓表面的金屬膜薄厚度不均,同樣構成元件製作上的缺陷

NR7-PY lift-off

resist is a simple, easy method for making metallic patterns on a

substrate, especially for those noble metal thin films such as

platinum, tantalum, nickel or iron which are difficult to be

etched by conventional methods.

NR7 side walls with a large undercut are required for lift-off

applications. The resists make possible fabrication of side

walls with high undercut. Edge profiles with steep edges or with

high undercut can be generated by varying the development time.

Using a minimum time for development, the resist side walls can be

made steep, and only a small undercut occurs in the middle region.

With over-development,

the undercut increases - and the resulting patterns are best

suited for use with lift-off techniques. gold, aluminum, and

nickel were used for sputtering, and the metals were deposited on

the resist patterns up to a height of 1

µm. No change in resist quality was

observed during the deposition process. After metal, the resist

patterns could easily be removed with acetone.

|

High Temperature Resists |

|

Resist

NR7-1000PY

NR7-1500PY

NR7-3000PY

NR7-6000PY |

Thickness

0.7µm - 2.1µm

1.1µm - 3.1µm

2.1µm - 6.3µm

5.0µm - 12.2µm |

Temperature resistance = 180°C

for metal evaporation and sputtering |

|

|

Enhanced Adhesion |

|

Resist

NR9-1000PY

NR9-1500PY

NR9-3000PY

NR9-6000PY

NR9-8000 |

Thickness

0.7µm - 2.1µm

1.1µm - 3.1µm

2.1µm - 6.3µm

5.0µm - 12.2µm

6.0µm - 25.0µm |

|

Temperature resistance = 100°C.

for metal evaporation |

|

|

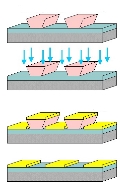

undercut |

Negative PR |

|

|

Metal

deposition |

|

PR

removal |

Advantage:

Easy to handle, fewer process steps

Temperature resistance up to

180 °C and adjustable undercut

Good line width

resolution

Deposite metal film by thermal evaporation

NR7-PY lift-off

resist can be

done using :

Acetone. Additional clean should be done using O2 plasma ash, or

photoresist developer, or Resist Remover

RR4

Metallization – deposition and etching

GaN Electronics For High Power, High

Temperature Applications

Methods for fabricating Ohmic contacts to

nanowires and nanotubes

AlGaN/GaN

Heterostructure FET — Processing and Parameters Evaluation

Advanced

Manufacturing Techniques for Next Generation power FET Technology

Si-CMOS-compatible

lift-off fabrication of low-loss planar chalcogenide waveguides

If you don't find what you're looking for,

Contact Us.

We may have a suitable product that's not listed, or we may be

able to develop a material to fit your specific needs.

Tel : (02)2217-3442 / Fax : (02)2704-4070

|